Automotive Projects

Manufacturing Execution Systems (MES)

Manufacturing Execution Systems (MES) are software solutions that monitor, track, and control production processes in real-time. MES bridges the gap between enterprise-level systems (like ERP) and the factory floor by managing production orders, scheduling, quality control, and traceability. It helps optimize manufacturing efficiency, reduce downtime, and ensure product consistency. By collecting live data from machines and operators, MES provides actionable insights for decision-making and continuous improvement. Common in industries like automotive, electronics, and pharmaceuticals, MES supports Industry 4.0 goals by integrating IoT, analytics, and cloud technologies to enhance overall production visibility and process reliability.

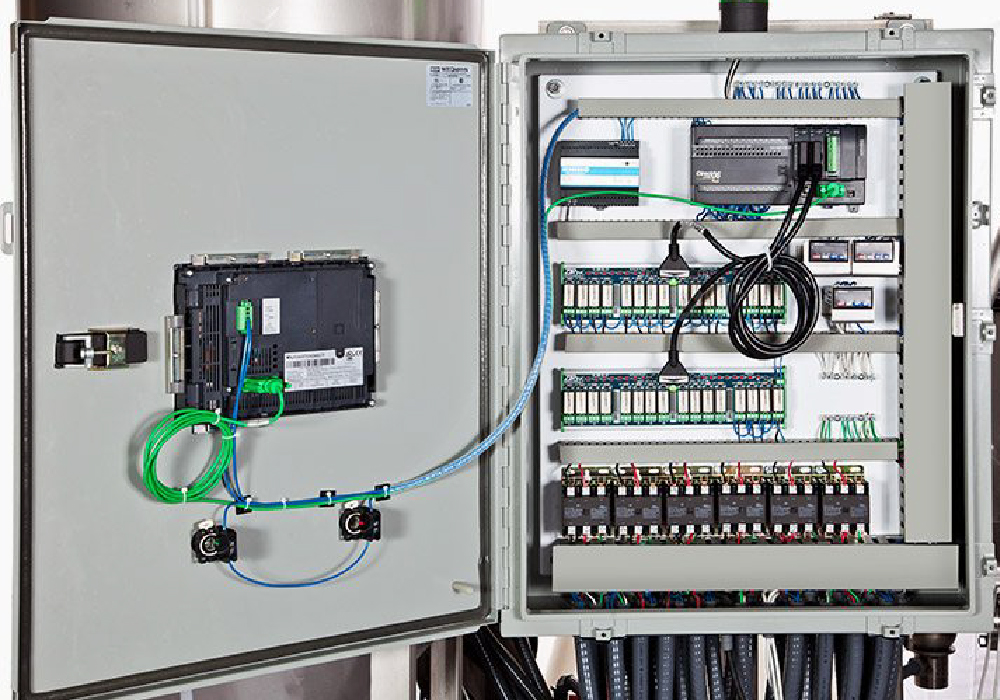

Assembly Line Automation Systems

Assembly line automation systems involve the integration of machines, robots, and control systems to automate repetitive manufacturing tasks. These systems improve production speed, accuracy, and consistency by minimizing human error and reducing labor costs. Automated assembly lines are designed for tasks such as part insertion, screwing, soldering, inspection, and packaging. They often include conveyors, programmable logic controllers (PLCs), sensors, and robotic arms. Modern assembly lines can be flexible, allowing for quick product changeovers. Widely used in automotive and electronics industries, automated systems increase throughput, maintain quality standards, and support lean manufacturing by optimizing material flow and cycle times.

Electric Vehicle (EV) Battery Management System

A Battery Management System (BMS) is vital for electric vehicle performance and safety. This project involves designing a BMS to monitor battery health, voltage, temperature, and state of charge (SoC). The system must balance cells, prevent overcharging, and optimize battery life. Advanced BMS units also use AI for predictive maintenance and energy optimization. Developing such a system requires knowledge in power electronics, embedded systems, and thermal management. EV manufacturers rely on efficient BMS designs to ensure consistent performance and battery longevity. The project also explores fast-charging compatibility and integration with vehicle energy management systems.

Advanced Driver Assistance Systems (ADAS)

ADAS enhances vehicle safety through technologies like lane-keeping assist, adaptive cruise control, blind-spot detection, and emergency braking. This project involves designing and testing such systems using radar, ultrasonic sensors, and cameras combined with computer vision and AI. By detecting vehicles, pedestrians, and lane markings, ADAS improves driver awareness and reduces accident risks. Simulators and real-vehicle testing help validate system reliability. Integrating ADAS into vehicles requires real-time processing and low-latency communication. This project is a stepping stone toward autonomous driving and requires multidisciplinary skills in mechatronics, AI, and control systems.

Automotive Telematics and Fleet Monitoring

This project focuses on designing a telematics system to collect and transmit vehicle data such as location, fuel usage, speed, and driver behavior. Using GPS, cellular communication, and cloud analytics, telematics improves fleet efficiency, reduces fuel costs, and enhances safety. Real-time dashboards provide insights for fleet managers to optimize routes, schedule maintenance, and ensure compliance. The system also includes geofencing and theft detection features. The project requires knowledge in IoT, embedded systems, and cloud-based data processing. With the growing need for smart logistics and connected vehicles, automotive telematics has become a key technology for modern transportation management.

Special Purpose Machine (SPM)

Special Purpose Machines (SPMs) are custom-designed machines developed to perform specific tasks with high efficiency and precision. Unlike standard machines, SPMs are tailored to a particular process such as drilling, tapping, pressing, or cutting, often used in mass production environments. These machines are equipped with dedicated fixtures, sensors, and automation systems to achieve faster cycle times and consistent quality. SPMs reduce manual intervention, increase productivity, and are cost-effective in high-volume operations. They are widely used in automotive, aerospace, and component manufacturing industries. Designing an SPM involves understanding the product, process, and required output to deliver optimal performance.

Pick and Place Robot System

Pick and Place Robot Systems are automated solutions designed to lift objects from one location and place them accurately in another. These robots are used in manufacturing, packaging, electronics, and food industries to handle repetitive tasks with speed and precision. Equipped with vision systems, grippers, and motion control, these robots can sort, assemble, or package parts based on size, shape, or location. Pick and place systems reduce labor costs, increase throughput, and improve product consistency. Integration with conveyor systems and sensors enables synchronized operations. These robots enhance workplace safety and are critical in high-speed production environments demanding reliability and accuracy.

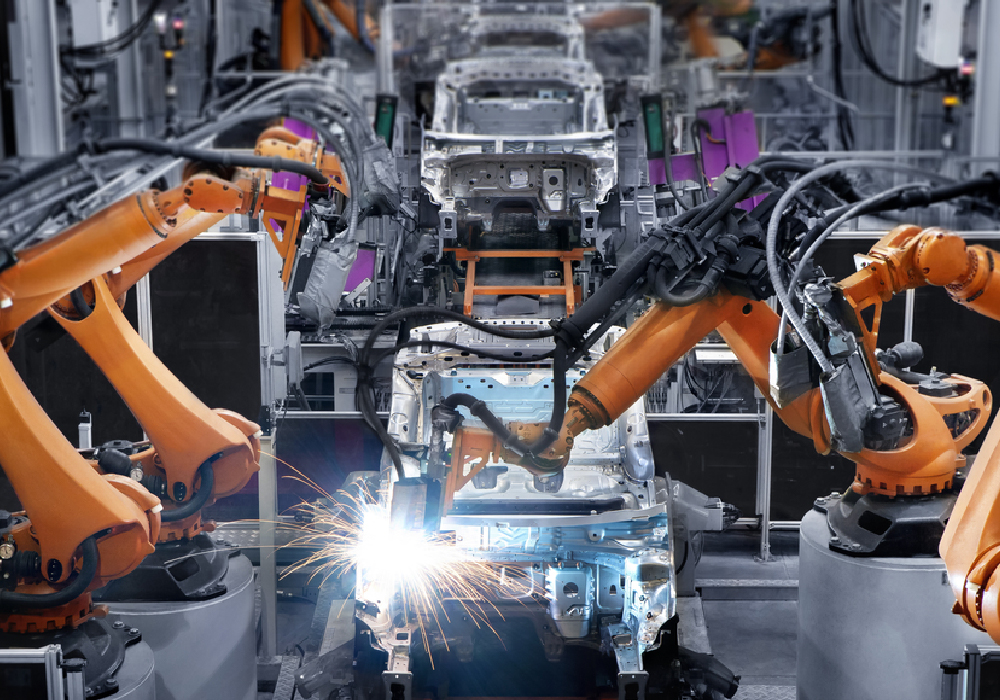

Engine Assembly Chain Conveyor System

An Engine Assembly Chain Conveyor System is a mechanized solution used to transport engine components through various assembly stages in automotive manufacturing. These conveyors ensure a continuous and controlled movement of parts, enabling synchronized assembly processes along the production line. The system often includes fixtures, lifting stations, sensors, and programmable controls to manage tasks like tightening, inspection, and component fitting. It reduces manual handling, increases production speed, and improves quality consistency. Chain conveyors are built to handle heavy loads and are customized for engine types and workflows. This system is essential for streamlining engine assembly while maintaining precision and safety.