Automated Guided Vehicle (AGV)

An Automated Guided Vehicle (AGV) is a mobile robot that follows predefined paths using magnetic strips, lasers, or sensors to transport materials within a warehouse or factory. It reduces labor dependency, ensures consistent material flow, and operates safely around humans. AGVs are used for pallet transport, assembly line supply, and goods movement. They integrate with warehouse management systems for route optimization. Common in manufacturing, logistics, and distribution facilities, AGVs help lower operating costs while increasing operational efficiency.

Autonomous Mobile Robot (AMR)

An Autonomous Mobile Robot (AMR) is a self-navigating robotic vehicle capable of understanding and reacting to its environment using AI and sensors. Unlike AGVs, AMRs do not require fixed paths; they adapt routes dynamically to avoid obstacles and optimize travel time. They are used in warehouses, factories, and hospitals for transporting goods, parts, or equipment. AMRs improve flexibility, reduce bottlenecks, and increase productivity. Integrated with IoT and warehouse software, they provide smart, scalable, and safe material-handling solutions.

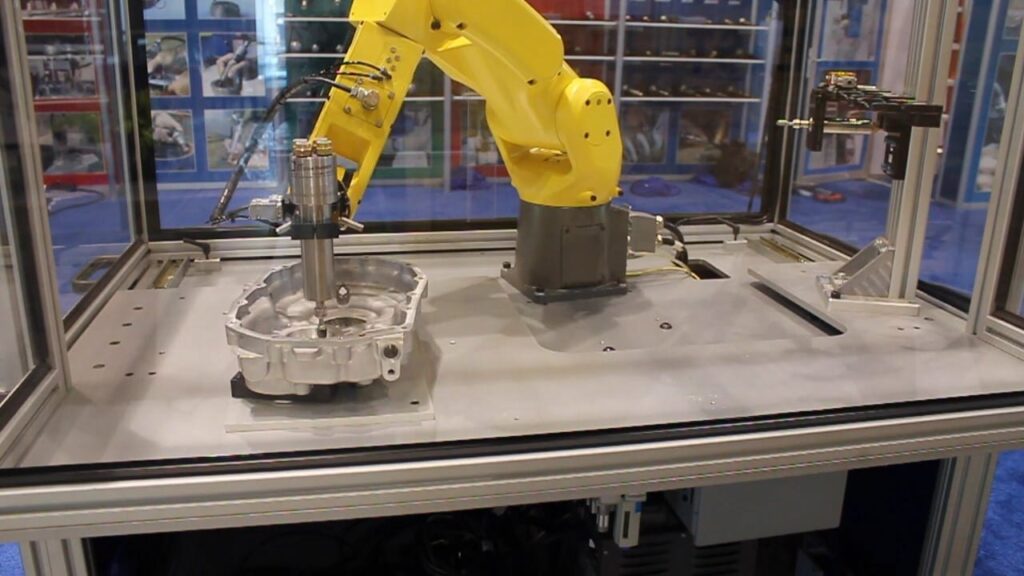

Deburring Robots

Deburring robots are automated systems designed to remove sharp edges, burrs, or residual material from machined components. Using tools like grinding wheels, brushes, or abrasive belts, these robots ensure smooth and safe surfaces. They improve product quality, extend component life, and enhance operator safety by eliminating manual deburring. Common in automotive, aerospace, and metalworking industries, deburring robots can work continuously with consistent precision. Integration with vision systems allows them to adapt to varying part shapes and sizes.

Pick and Place Robot System

A pick and place robot system automates the process of picking up objects from one location and placing them in another with high speed and precision. Using robotic arms, grippers, and vision guidance, these systems handle parts, products, or materials in manufacturing, packaging, and assembly operations. They increase throughput, reduce labor costs, and ensure consistent handling. Pick and place robots are used in industries such as electronics, food processing, and pharmaceuticals, offering flexibility for different product sizes and configurations.