End-of-Line (EOL) System

An End-of-Line (EOL) system is used in manufacturing to perform final testing, inspection, and packaging before products are shipped. It ensures that goods meet quality, safety, and performance standards through automated checks such as functional testing, visual inspection, and labeling. EOL systems often integrate robotics, conveyors, and vision systems for high-speed, accurate operations. They reduce human error, improve throughput, and provide traceability. Commonly used in automotive, electronics, and consumer goods production, EOL systems help maintain brand reliability.

Car Parking System

An automated car parking system is designed to maximize parking capacity in limited spaces using mechanical or robotic handling. Vehicles are automatically moved to designated slots using lifts, conveyors, or shuttle systems without the need for human drivers inside the structure. These systems reduce land usage, improve safety, and eliminate the need for large ramps or wide driveways. Widely used in urban areas, malls, airports, and residential complexes, automated parking solutions provide efficient, space-saving, and eco-friendly vehicle storage.

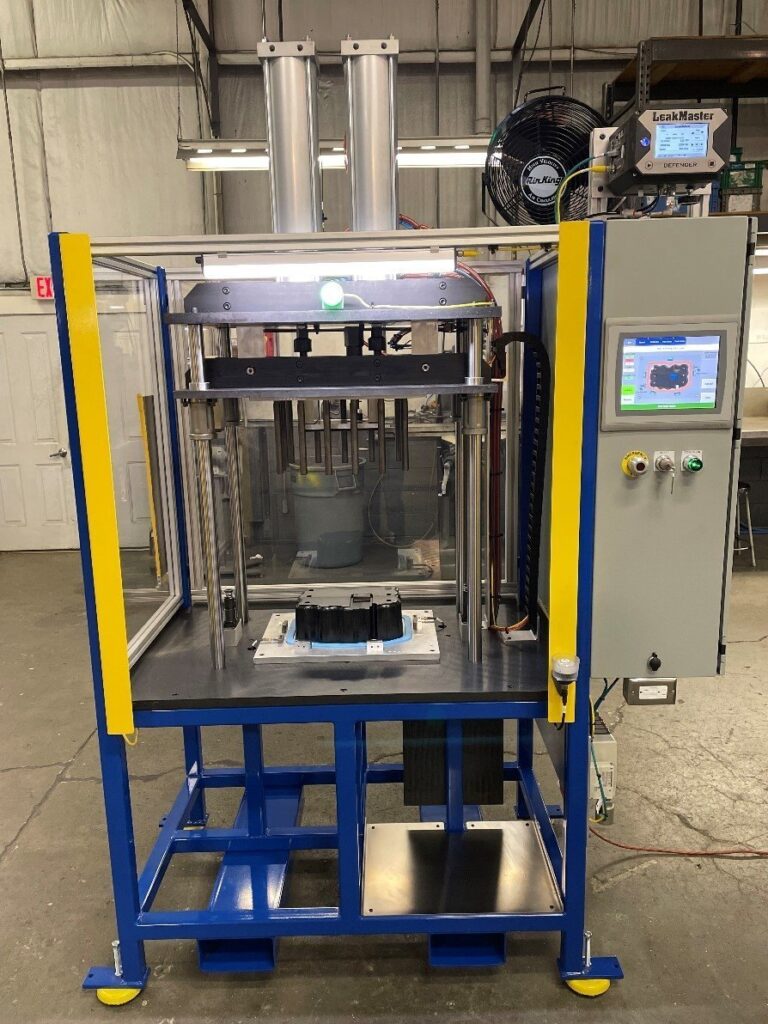

Leak Tester

A leak tester is a specialized machine used to detect and measure leaks in products, components, or assemblies. It uses methods such as air pressure decay, vacuum, or helium mass spectrometry to identify leakage points. Leak testing ensures product integrity, prevents fluid or gas escape, and meets safety and regulatory standards. Industries like automotive, aerospace, medical devices, and packaging rely on leak testers to maintain quality control. Automated leak testers can be integrated into production lines for continuous inspection.